X-Ray Fluorescence Core Scanner Core Surface Preparation Guide

Sediment surface of the core should be as flat and smooth as possible. Fine grain sediments provide better results than a surface with larger grain size sediments that have a higher porosity. Cores with extremely coarse grain size or porous sediments should not be scanned using the XRF. Areas dominated by pebbles, shell fragments, shells, corals, or sharp edges can puncture the film and should be avoided when scanning core sections on the XRF core scanner. It is important to log and skip these areas while scanning core sections. Areas on the core surface that are uneven can be flattened out using special tools to flatten the surface as best as possible.

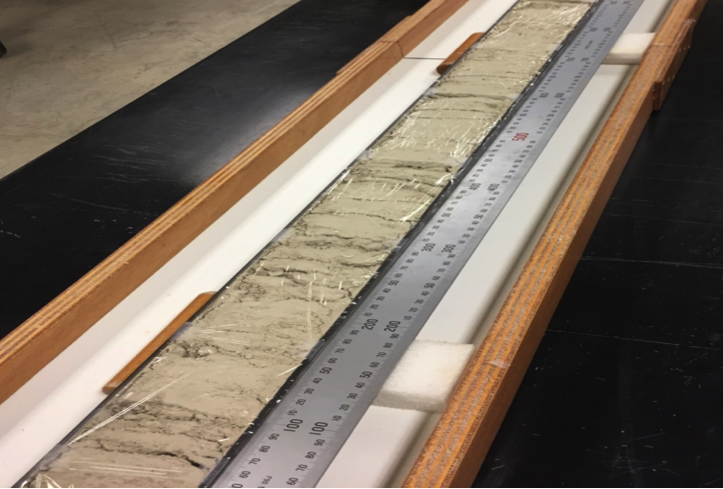

The length of the core should be recorded.

The XRF runs in millimeters, not centimeters (e.g. 150 cm = 1500 mm).

Sediment surface of the core should be as flat and smooth as possible.

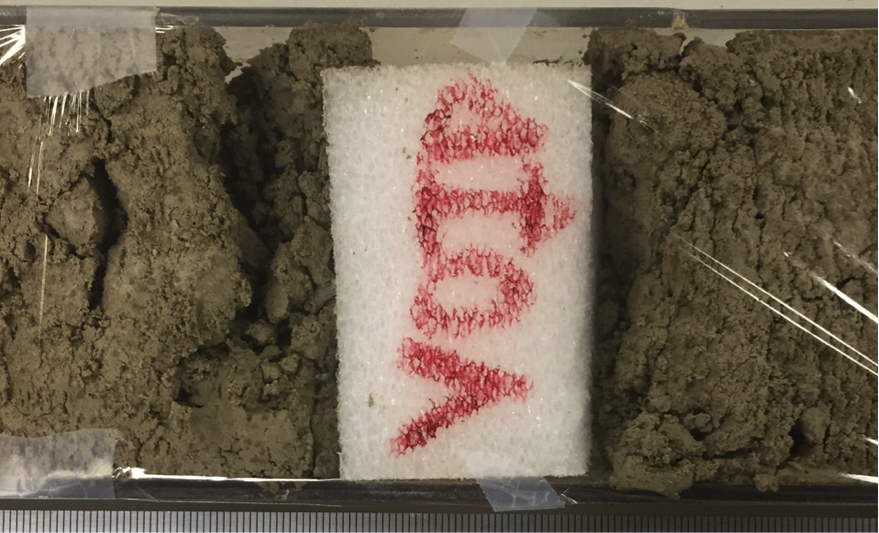

Shell fragments and coral fragments are too big: does not make sense to measure the sediment. Rough edges will break the film!

Core sections that are highly disturbed, have large cracks, or have areas with no sediment, or a void, should be skipped.

Before running the core please check what the end caps look like.

Carefully cut away the liner to meet the core surface. The core caps can be carefully cut away if there is a risk of sharp ends sticking out.

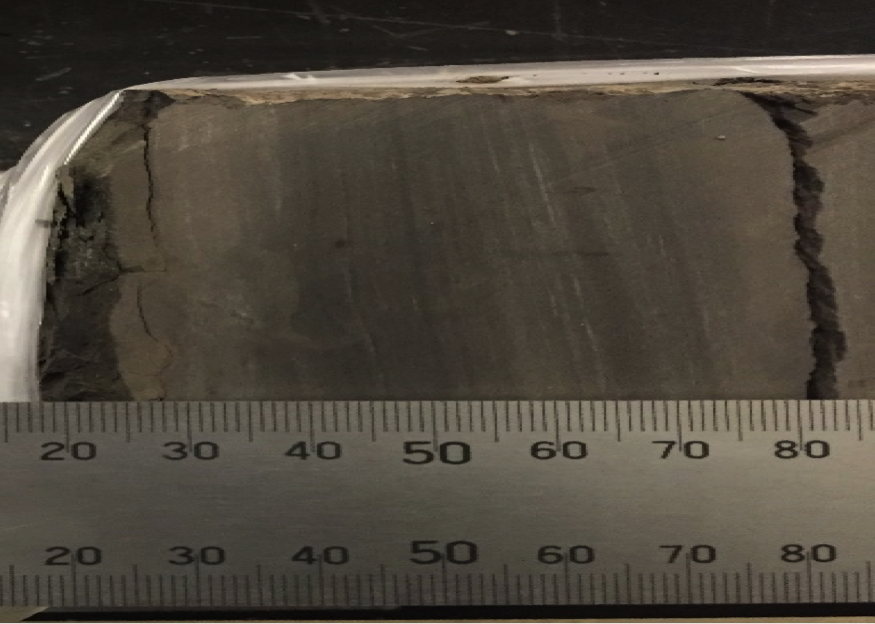

Good cross section of the core surface. The plastic liner will not interfere with the XRF measurements.

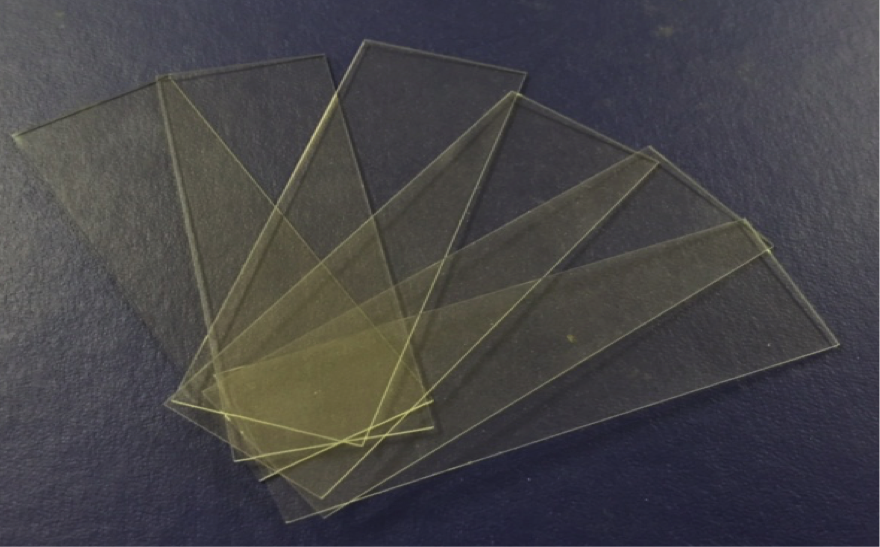

To avoid chemical contamination use glass slides for scrapping the surface of IODP core sections. Other core sections may be treated with scarpers and knifes.

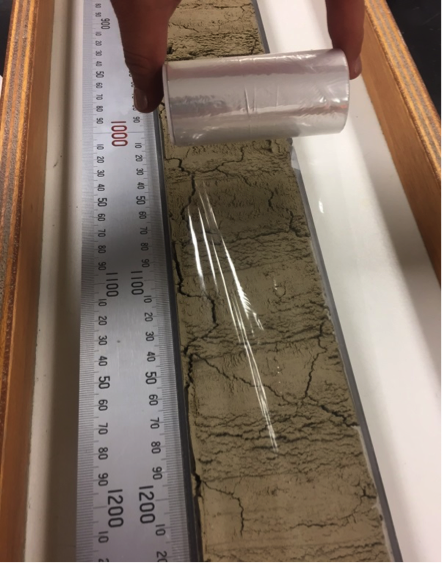

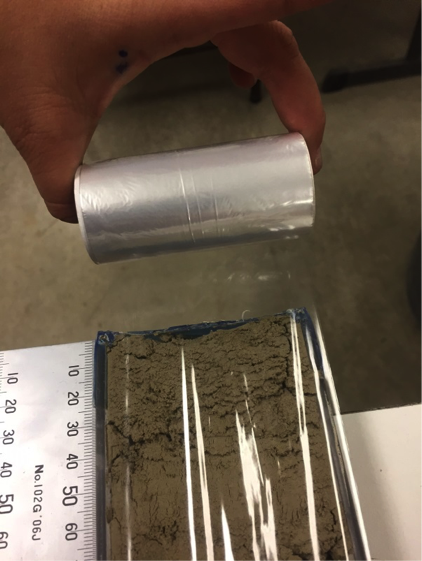

Ultralene film is applied to the surface of the core sections to avoid contamination. The film should be placed as carefully as possible on the sediment surface. When applying the film avoid or minimize wrinkles and bubbles. Proper tools (i.e. roller or KIM wipes) work best to help flatten the film.

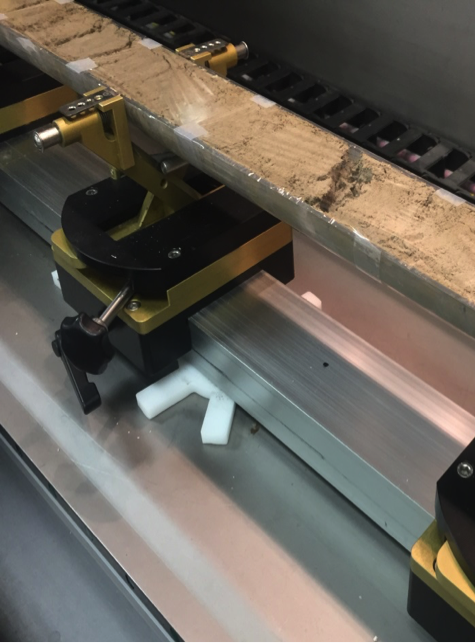

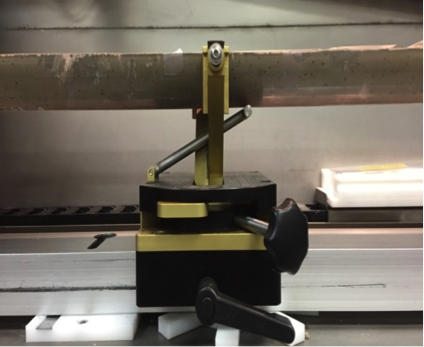

Place the core sections horizontally into the core holders in the XRF scanner. Tighten the core holders by moving the handle to the right, raising the core section in an upward direction.

Make sure to measure and write down:

- Length of the core section (measured in mm)

- Note any additional measurement positions, or “add” positions

- Measurement positions that will be avoided, or “skip” positions